Deep Blue Paper Backpack

R1,599.00

– Made from two layers of reclaimed cement paper.

– Fused to cotton canvas for extra strength

– Padded base.

– Inside pocket.

– 100% cotton webbing shoulder straps.

– There is a top handle to carry the bag.

– Adjustable shoulder straps.

– Is water resistant (read more about this innovative coating and Wren materials).

COLOUR INSPIRATION:

Deep blue is a rich and intense shade of blue that is often associated with the depths of the ocean or the vast expanse of the night sky. It is a dark and captivating hue that evokes a sense of mystery, calmness, and tranquility. Created by blending black or navy blue, it emits a muted yet captivating tone.

DIMENSIONS:

28.5cm(W) x 37cm(H), base: 27cm(W) x 10cm(D)

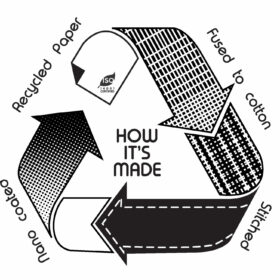

HOW IT IS MADE: Wren’s “cement” kraft paper is sourced from local packaging printing factories, retaining a link to their origins with cement bags (you can read the story here). Even today, there remains a strong link to cement because Wren uses the same type of paper, but from a different source.

HOW IT IS MADE: Wren’s “cement” kraft paper is sourced from local packaging printing factories, retaining a link to their origins with cement bags (you can read the story here). Even today, there remains a strong link to cement because Wren uses the same type of paper, but from a different source.

The packaging print factories discard the ends of paper reels due to creases, imperfections, or their small size, and Wren acquires the paper from them. Wren’s process combines the concepts of recycling, reclaiming, upcycling, and repurposing.

Once delivered the reel-ends of paper are slit into large sheets that get delivered to a local screen printing company. Using specially prepared ink with a unique recipe to flood the screen and print the paper. Some colours require multiple screen floods, and weather conditions impact the final colour outcome. Certain colours are printed on bleached kraft paper, offering a cleaner and brighter tone, while others are printed on natural kraft paper, offering a dustier and darker shade.

After printing, Wren’s expert team of makers (meet the team) meticulously hand-cut, fuse with cotton, stitch, and coat the paper with environmentally-friendly Nano Liquid Glass for water resistance.

More information about Wren’s paper, coating, printing, and packaging can be found here.

| Coating | Wren paper products are coated with Nano liquid glass, making them water, dirt and oil resistant. This is an environmentally friendly coating. |

|---|---|

| Materials | Reinforced paper, press studs, cotton webbing, brass coated metal adjusters and loops, batting, foam, cotton fabric |

| Weight | 910g |

| Care Instructions | Unlike fabric, paper is smooth and dirt does not naturally cling to it., If your product does get some marks on it that you do not like you can gently try to an eraser. Be careful of rubbing too hard as this may remove some parts of the Nano protective coating., OIL: If you get an oily mark on the paper that the Nano was unable to resist, try putting some bi-carb or baby powder on the mark overnight. The powder will “absorb” the mark and make it disappear., WATER: If you find yourself dashing between buildings and using your WREN product as an umbrella (which we do not recommend), wipe the excess water off it as quickly as possible., The Nano layer is protective but does not make the product waterproof. We also discourage scuba diving with Wren products., STUBBORN MARKS: If a mark refuses to budge, we suggest grabbing any permanent marker and making a feature of it. Add eyes, doodle over, write a message – anything. Make it your unique mark! |

| Take Note | Some pigment mixtures have a mysterious quality to them: Like a new pair of jeans, some of the pigment from the this rich colour may rub off for the first few days of use. |

Quality workmanship and service

Quality workmanship and service

Every product is quality checked by 3 people to ensure there are no tears in the paper, unravelling stitches or faulty studs. We have an very high quality standard. If something happens that is a manufacturing fault, please let us know so that we can make it right.

Better with time

Better with time

The paper has been referred to as wearing like leather. The paper softens, the product becomes "worn-in", and acquires a unique patina. Through everyday use the creases become tonal patterns and are visual marks of your life. We hope that these marks are of adventure, travel and happy days.Read More.